Gostaresh Ahan Rah Company’s strategy is to increase safety factors, health, and environment, and develop social responsibility to increase safety and health factors of the employees in detritus extraction activities, making the operations safe based on principles, according to rock climbing standards, and creating the required infrastructure . Detritus extraction and removal take place in hazardous trenches along the railway tracks to prevent soil and rocks from falling on the tracks. Weak and weathered soil and rocks are identified and extracted, and then collected and removed using a permanent way motorized car with a loading crane. Considering that detritus extraction is the extraction of soil and rock from the trenches and is carried out by a person at heights, it somehow resembles rock climbing, therefore all rock climbing safety protocols like training, equipment, etc. must be considered. This report embodies the actions that have been carried out for the first time in the General Administration of Azerbaijan Railway to improve the safety of detritus extraction in a standard manner. These actions are described fully in 4 chapters and their implementation has been documented.

1.1. Defining detritus extraction and the reasons to do it

Technical building groups perform controlled extraction of soil and rocks in the hazardous trenches along the railway tracks because there is a possibility that these weak soil and stones fall spontaneously and close the railway track or fall on the railway machines. This requires the physical presence of an individual on the trench extracting the hazardous stones using a crowbar. Considering the fact that one of the necessities of this activity (regarding its nature) is the individual being suspended in the trench, it is somehow similar to rock climbing.

1.2. Risks and dangers of detritus extraction

Considering the aforementioned points in detritus extraction, its risks and dangers include the detritus extractor’s fall from the height due to not using standard safety equipment for work and tearing of non-standard ropes, other group members’ fall due to unprincipled and high-risk procedures and executive methods, the occurrence of musculoskeletal conditions in personnel, rocks falling on detritus extractors, lack of training in the detritus extractor personnel, etc.

In the old method, the detritus extraction was carried out completely following the traditional methods, relying on the individual’s strength and using hemp rope. In this method, the climber ties a hemp rope around his waist and moves down the trench without any rock climbing safety equipment, and the end of the rope is held by one or more people at the top of the trench. (This discrepancy itself will lead to the risk of the people holding the rope falling and results in the occurrence of catastrophic events for several people.) In this method of detritus extraction, the individual (extractor) was only held by the rope tied around his waist and the people who held the end of the rope at the top of the trench. The occurrence of any human error caused by the supporting people would lead to dire accidents and falls. Also, in trenches that have steep slopes, the supporting people who held the rope had to come to the edge of the trench to communicate with the extractor, which raised the risk of slipping and falling of the supporting people and the extractor down the trench.

Below are some pictures of the old and traditional method of detritus extraction.

|  |  |

3-1- Introduction of equipment and the use of each of them

| Safety helmets with chin strap | |

|---|---|

| A safety helmet can prevent damage to the head. These damages can happen in these situations: • Hitting or falling of objects on the head • Head collision with fixed objects |  |

| Safety shoes | |

| While extracting detritus the danger of being hit on the food by the rocks is common. The safety shoes’ responsibility is to protect the foot from falling objects, slipping, or sliding. |  |

| Anti-wear safety gloves | |

| Work gloves should be used to protect hands from hazards including cuts, abrasions, and crushing. The reason to use anti-wear gloves is to prevent hands from slipping while ascending or descending using the static rope and also to prevent damage to the hands while extracting detritus. |  |

| Full body safety belt (full body harness) | |

| It is a piece of equipment that gives the detritus extractor more safety factors. The harness is used in ascending, descending, supporting, and carrying the technical equipment of the extractor. |  |

| Static rope | |

| The rope is one of the most important pieces of equipment used in detritus extraction and in fact has the main responsibility of protecting the extractor’s life. The rope is used to connect the extractor to anchors used for ascending and descending. They are available in different diameters. In terms of resistance, rock climbing ropes are divided into two categories: stretchable (dynamic) and non-stretchable (static). We have used static ropes here. (Before safety improvements in the detritus extraction activity and using standard equipment, hemp ropes were used.) |  |

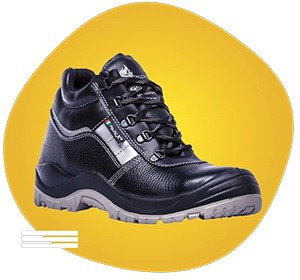

| Karabiner | |

| In rock climbing, there is a piece of equipment called a karabiner. In fact, a karabiner is a metal device made of aluminum alloy, which is used to connect rock climbing equipment. The karabiner is made in two general shapes, D and pear, in simple and screw forms, each of which has specific applications in rock climbing. . The resistance (the weight they can carry) of the karabiner is written on its body. Karabiner components include the main body, latch, spring, pin, and screw karabiner also has nuts and bolts. |  |

| Sling | |

| Sling is another rock climbing equipment where two karabiners are installed on both sides of a strap. Sling is another rock climbing equipment where two karabiners are installed on both sides of a strap. This tool is used for connection during climbing. . It is also used for anchor installation. 60cm sling is used in detritus extraction. |  |

| Jumar | |

| Jumar is a piece of equipment for safe and fast climbing using a fixed rope. It is also used in different places, but it is generally used in climbing operations. The way of climbing using a Jumar is step by step. Jumar has a handle that can be easily moved along the rope. Jumars are made for the left-handed and right-handed, and right-handed Jumar was used in the detritus extraction operation. |  |

| Grigri | |

| Grigri is a piece of equipment in rock climbing for ascending and assistance using a rope. This assisting equipment locks in the event of a sudden fall of the extractor and has a function similar to a car seat belt. |  |

| Lanyard | |

| Using a proper 5mm diameter lanyard and a standard knot (Prusik), you can move along the climbing rope easily. It is also used in installing the anchor. |  |

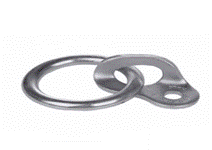

| Anchor installation plate | |

| It is a steel washer that has a loop and is fixed on the rock or the concrete using an anchor bolt for creating bottom or middle anchors. |  |

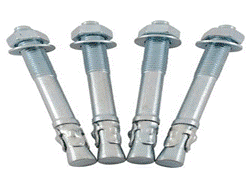

| Anchor bolt | |

| It is a type of screw that is used to install anchor installation plates on hard and rocky parts. An anchor bolt is a type of screw that after being inserted in the rock or the concrete expands itself inside and cannot be removed. |  |

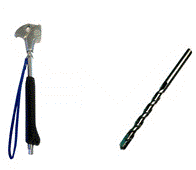

| Tools for inserting screws on rocks | |

| There are hammers, drills, and hand drills. They are used for inserting anchor bolts in rocks or concert to create main or middle anchors using an anchor installation plate. |  |

| Vertical poles for anchor installation | |

| These poles are made of size 6 heavy wide flange beams and size 10 plain bars with a height of 50 centimeters and are used in trenches with weak soil where installing the anchor plate is not possible. (Making these poles to install anchors in heights for detritus extraction is one of the company’s innovations.) |  |

2-3- Theoretical and practical training to enhance detritus extraction safety

After needs assessment and purchasing of detritus extraction equipment for 11 active detritus extraction groups (technical buildings) at the maintenance and repairs of tracks and buildings of Azerbaijan Railway level; to hold theoretical and practical training courses for these groups, the company started cooperation with a rock climbing coach certificated by the Azerbaijan Province Mountaineering Commission. The training was done in two parts: theoretical and practical. This training course aimed to enhance the safety of detritus extraction operations by teaching how to install the anchor and safe keeping of the individual while ascending and descending during detritus extraction. The theoretical part of the training began with an introduction to all rock climbing equipment (sections 1-3) and the types of knots used in rock climbing, and after the presentation of the material by the rock climbing coach, the instructed items such as how to use knots were practiced by the participants in a practical way under the supervision of the coach. The next stage of the training was held practically with the presence of all participants in the kilometer 799+800 trench. In the practical part of the training, the natural and artificial anchors (using the installation plate and anchor bolts for rock and concrete, using vertical poles for installing the anchor in weak soils) and their installation methods were described and performed practically by all the participants.

3-3- The training for installing anchors for working on heights

1-3-3- Work permit system for the safety of detritus extraction activities

1-1-3-3- Definition of the work permit and its usage in detritus extraction activities:

A detritus extraction work permit is a document that shows the necessary permits from the authorized people (HSE authority/expert responsible for the operation) to carry out the work by authorized employees (detritus extraction teams of technical buildings) at a certain time (one day before the start of the activity) and a certain place issued from the safety point of view. In this permit, risks and control measures appropriate for the type of work are identified and executed. The purpose of formulating this executive procedure is to provide a practical procedure to ensure the establishment of safe conditions in detritus extraction. Generally, the main goals of formulating and implementing this document are as follows:

• Ensuring the implementation of safe methods to prevent possible accidents caused by dangerous conditions

• Ensuring the proper functioning of the permitting system and its correct cycle of process

• Notifying the personnel of the HSE department and performing risk control measures to make the environment and operations safe

• Determining the required equipment and the location of the area where the activity is carried out

• Informing affected units and areas of the activity in terms of working conditions and procedures to prevent repetitive work

* The supervisors of the detritus extraction teams are obligated to obtain a permit the day before the execution of the extraction. A sample work permit form for detritus extraction is on the next page. A sample work permit form for detritus extraction is on the next page.

|  |  |  |

After needs assessment and final studies to purchase and equip the work in heights equipment, and holding theoretical and practical training courses for the detritus extraction groups (technical buildings) present in the maintenance and repairs operation of tracks and technical buildings of Azerbaijan Railway (11 active groups), it was decided that after equipping and holding training courses for all detritus extraction groups (technical buildings), the new principled method will replace the traditional method and will be used in future detritus extractions. Currently, 8 teams out of 11 maintenance teams have been equipped in the operation of tracks of Azerbaijan Railway, and the remaining 3 teams will be equipped by the end of June. Also, theoretical and practical pieces of training will be completed in all teams. It is worth mentioning that this method has been implanted successfully in some detritus extraction groups and now is in progress. The following pictures are examples of performing the detritus extraction activity by the technical building team of the Ajab Shir area using the principled method that has been described in the order of priority of preparation.

Since 1988, falling from heights has accounted for a large number of work-related injuries in the world, and the most common cause of death of workers in the workplace is related to falling from heights. Based on the statistics reported by the Ministry of Cooperative Labor and Social Welfare in 2019, falling from heights was responsible for 44% of work-related deaths. This shows the importance of timely identification and elimination of the risk of falling from heights in the workplace. Also, according to the requirements of national safety rules and regulations to enhance the safety of the activities of employees at heights, under controlling the risks of possible catastrophic events, the detritus extraction in the Islamic Republic of Iran Railway Company is one of the activities deemed high risk which can lead to unfortunate and irreparable accidents in the system. Therefore, it is suggested that in the General Administration of the Railway Districts of the Islamic Republic of Iran, where the detritus extraction is being executed, the safety of operations should be carried out through safety and standard methods of working at heights. It is also suggested to plan a system considering the specialization of safety equipment and personal protection of working at heights (referring to the introduction of equipment in this report) and the high price of safety equipment for working at heights (compared to other personal protection equipment). Regarding the importance and risks associated with the occurrence of accidents, these costs should be considered by the employers and contractors who are going to provide services in the field of technical buildings.